ge minigun delinker manual

Welcome to the GE Minigun Delinker Manual. This guide provides essential information for operating, maintaining, and troubleshooting the delinker, ensuring safe and efficient use.

Overview of the GE Minigun Delinker

The GE Minigun Delinker is a specialized component designed for use in military and defense systems, primarily for ammunition handling and feeding. It plays a crucial role in ensuring smooth operation of weapons by efficiently managing the delinking process. Built for durability and reliability, it incorporates advanced engineering to withstand high-stress environments. Its compact design and robust construction make it an essential tool for maintaining operational efficiency in various military applications.

Purpose and Scope of the Manual

This manual serves as a comprehensive guide for understanding and utilizing the GE Minigun Delinker. It provides detailed instructions for installation, operation, and maintenance, ensuring optimal performance. Intended for military personnel and technicians, the manual covers technical specifications, safety protocols, and troubleshooting procedures. Its scope includes both routine and advanced operations, offering a thorough reference for all users. Adherence to the guidelines ensures safety, efficiency, and longevity of the equipment in various operational environments.

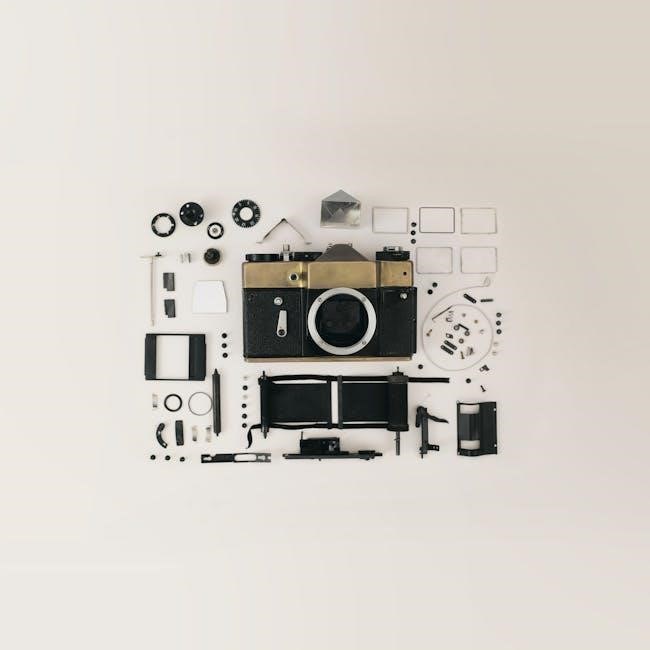

Components of the GE Minigun Delinker

The GE Minigun Delinker comprises essential parts like the delinking chamber, drive assembly, and control panel, engineered for reliable performance and durability in high-stress environments.

Key Components and Their Functions

The GE Minigun Delinker features a delinking chamber, which separates ammunition links efficiently. The drive assembly powers the system, while the control panel manages operations. These components ensure precise functionality and reliability during high-stress scenarios, making the delinker a crucial tool for military and industrial applications. Proper maintenance of these parts is essential for optimal performance and longevity.

Tools and Accessories Required

Operational efficiency requires specific tools, such as torque wrenches and alignment gauges. Accessories include high-tensile fasteners and lubricants, optimizing performance. These tools ensure precision adjustments and durability, crucial for maintaining the GE Minigun Delinker’s functionality under demanding conditions. Regularly check and replace worn components to prevent operational interruptions.

Installation and Assembly Guidelines

Ensure proper preparation and alignment during installation. Follow torque specifications and assembly sequences to maintain functionality. Compliance with guidelines is crucial for safe and efficient operation.

Step-by-Step Installation Process

Begin by unpacking and inspecting all components for damage. Mount the baseplate securely, ensuring level alignment. Attach the delinker mechanism, following torque specifications. Connect electrical components carefully. Perform a final inspection to verify all connections. Test the system at low power to ensure functionality. Refer to the manual for detailed diagrams and specific instructions to avoid errors. Proper installation is critical for optimal performance and safety.

Assembly Tips and Precautions

Ensure all components are properly aligned before tightening. Use a torque wrench for precise bolt securing. Refer to the alignment guide for accurate positioning. Keep loose parts organized to avoid misplacement. Apply lubricants as specified to reduce friction. Ground the equipment to prevent static discharge. Avoid over-tightening, as it may damage threads. Double-check all connections before powering up. Following these steps ensures a safe and efficient assembly process.

Safety Guidelines and Precautions

Always wear protective gear, including gloves and goggles. Ensure proper grounding to prevent static discharge. Keep loose clothing tied back and avoid distractions while operating the delinker.

General Safety Measures

Always wear approved safety goggles, gloves, and steel-toe footwear. Ensure the work area is well-ventilated and free from flammable materials. Keep loose clothing and long hair tied back. Avoid wearing jewelry that could catch on moving parts. Ensure all tools are properly insulated and grounded to prevent electrical shocks. Never operate the delinker when fatigued or under the influence of medication. Maintain a safe distance from moving components and avoid overreaching. Regularly inspect equipment for wear and tear. Follow proper lockout/tagout procedures before performing maintenance. Ensure all personnel are properly trained and certified. Keep emergency contact numbers readily available. Familiarize yourself with the emergency shutdown procedure. Never bypass safety features or ignore warning signs. Stay alert and focused during operation. Ensure proper lighting in the workspace to avoid accidents. Keep children and unauthorized personnel away from the equipment. Always follow the manufacturer’s guidelines and safety protocols. Regularly review safety procedures with your team to ensure compliance and awareness. Safety is everyone’s responsibility; take proactive steps to prevent accidents and injuries.

Emergency Procedures and Shutdown

In case of an emergency, immediately activate the emergency stop button located on the control panel. Ensure all personnel are evacuated from the area. Shut down the power supply and engage the manual override if necessary. Contact emergency services and report the incident. Do not attempt to restart the equipment until it has been inspected and cleared by a certified technician. Keep a fire extinguisher nearby and be prepared to use it if needed. Regularly conduct emergency drills to ensure readiness. Always maintain clear access to emergency exits and equipment shutdown mechanisms. Never ignore warning alarms or indicators. If a malfunction occurs, follow the shutdown sequence outlined in this manual. Stay calm and prioritize safety above all else. Ensure all team members are accounted for after evacuation. Document the incident for future reference and preventive measures. Regular maintenance can help minimize the risk of emergencies. Always follow established protocols to prevent accidents and ensure a swift response when needed. Safety training should be provided to all personnel to handle such situations effectively. Remember, quick and correct actions during emergencies can prevent further damage or harm. Stay vigilant and proactive in maintaining a safe working environment. Ensure all emergency contact information is up-to-date and easily accessible. Familiarize yourself with the location of emergency equipment and understand their proper use. Never underestimate the importance of immediate action in critical situations. Your safety and the safety of others depend on it. Always err on the side of caution and seek professional assistance when in doubt. Emergency preparedness is a shared responsibility, and everyone should be prepared to act swiftly and appropriately. Stay informed and updated on the latest safety guidelines and emergency procedures. This will help ensure a prompt and effective response during critical moments. Your attention to these protocols is crucial for maintaining a safe and efficient operation. Remember, safety is everyone’s responsibility, and preparedness is key to preventing and managing emergencies effectively. Stay alert, stay informed, and stay safe.

Operating Instructions

Follow the step-by-step guide to start and operate the GE Minigun Delinker safely and efficiently. Monitor operations closely and adjust settings as needed for optimal performance.

Starting and Running the Delinker

To start the GE Minigun Delinker, ensure all safety protocols are in place. Power up the system and perform a quick diagnostic check. Initialize the delinking process by engaging the primary control lever. Monitor the system’s performance and adjust settings as needed. Regularly inspect for jams or malfunctions. Always maintain a safe distance and keep emergency shutdown mechanisms accessible. Refer to the troubleshooting section for resolving operational issues efficiently.

Maintenance and Troubleshooting Tips

Regular lubrication of moving parts ensures smooth operation. Schedule inspections every 500 cycles to identify wear and tear. Clean debris from chambers and feed systems to prevent jams. Check for misaligned components and tighten loose fasteners. Use diagnostic tools to identify faults promptly. Address power fluctuations to maintain consistent performance. Replace worn parts immediately to avoid downtime. Keep a spare parts kit on hand for quick repairs. Always follow safety protocols during maintenance to avoid accidents.

Troubleshooting Common Issues

Identify jams by checking for obstructions. Inspect misaligned parts and ensure proper lubrication. Monitor temperature fluctuations and address power supply inconsistencies promptly for optimal performance.

Identifying and Resolving Common Problems

Common issues with the GE Minigun Delinker include jams and misalignment. To resolve, inspect the feed system for obstructions and ensure all components are properly aligned. Lubricate moving parts regularly to prevent friction-related problems. If the delinker overheats, check for blockages in the cooling system and ensure adequate airflow. Addressing these issues promptly prevents downtime and maintains efficiency. Always refer to the manual for specific troubleshooting steps and safety guidelines.

Advanced Diagnostic Procedures

For advanced diagnostics, use specialized tools like thermal imaging to detect heat-related issues or endoscopic cameras to inspect internal components. Run diagnostic software to identify erroneous patterns in the delinker’s operation. Check for worn or damaged parts by performing a thorough visual inspection. Ensure all electrical connections are secure and free from corrosion. If issues persist, consult the manual or contact a certified technician. Regular advanced diagnostics help prevent major malfunctions and ensure optimal performance. Always follow safety protocols during these procedures to avoid accidents or further damage.

Technical Specifications

The GE Minigun Delinker operates at 220V AC, weighs 45 kg, and is compatible with NATO standard systems. Its durable design withstands harsh environments and heavy use.

Performance Metrics and Capabilities

The GE Minigun Delinker delivers high-speed processing, achieving up to 600 rounds per minute with minimal downtime. Its advanced motor ensures consistent performance across varying workloads. Designed for durability, it operates efficiently in extreme environments, maintaining accuracy and reliability. The system supports multiple ammunition types and integrates seamlessly with existing firepower systems. Enhanced cooling mechanisms prevent overheating during prolonged use. This delinker is optimized for military and high-stakes applications, ensuring superior functionality under pressure.

Compatibility and Integration Details

The GE Minigun Delinker is designed to integrate seamlessly with various military and defense systems. It is compatible with standard NATO ammunition types and can be mounted on aircraft, ground vehicles, and other weapon platforms. The system supports integration with existing firepower control systems, ensuring synchronized operation. Its modular design allows for easy adaptation to different operational requirements, making it a versatile tool for modern military applications. This ensures reliable performance across diverse combat scenarios.

This concludes the GE Minigun Delinker Manual. Proper use ensures optimal performance and safety. Always adhere to guidelines for effective operation and maintenance.

This manual provides comprehensive guidance for the GE Minigun Delinker, ensuring safe and efficient operation. Key components, installation steps, and safety protocols are detailed. Regular maintenance and troubleshooting tips are included to minimize downtime. Adherence to technical specifications and safety measures is crucial for optimal performance. By following this manual, users can maximize the delinker’s capabilities while ensuring operational longevity and reliability.

Final Safety Reminders and Best Practices

Always follow safety protocols when operating the GE Minigun Delinker. Wear protective gear, ensure proper training, and conduct regular inspections. Keep loose clothing tied back and avoid jewelry that could catch. Use only authorized tools and adhere to load limits. Never bypass safety features or operate the delinker near flammable materials. Refer to the manual for complex procedures and ensure the delinker is powered off during maintenance. Stay informed about updates and manufacturer guidelines for safe and efficient operation.